Ultrasonic cleaning and preservation equipment to clean and preserve tools of plastic or aluminium die casting manufacturing

Cleaning of extrusion tools with ultrasound

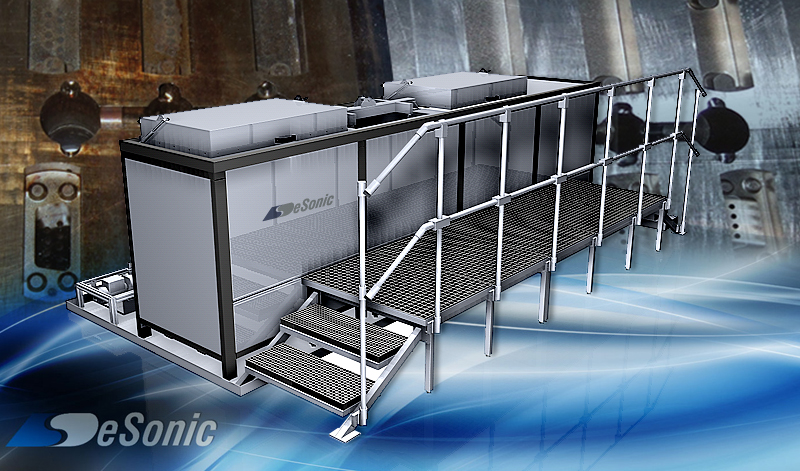

Cleaning of extrusion tools and moulds for plastic and aluminium die casting manufacturing which predominantly in strong alkaline cleaner water-based, often even pure used disassembled forms part, cleaned in an ultrasonic frequency to the 25 kHz.Thereby, the mould sections with load crane directly on a grill or in a shopping cart located about a heavy load lifting system of the equipment are inserted in the ultrasonic bath.

The avoidance of intense, time-consuming hand cleaning and to improve the cleaning performance is the advantages of ultrasonic cleaning. Also "", may be caused by the machining by hand brushes, scraper, or scratches, damage.

As a succession process the mould sections are abgspült after cleaning with clear water. This prevents the spreading of residues, E.g. Reiniungsmittel or dissolved but not yet from suspended particles in the following production processes. To a corrosion of defatted / cleaned to avoid forms, this will involve after rinsing the preservation, which consists of a plunge pool with a water-displacing agent,. In a short - or long-term corrosion protection is applied to the entire surface. Finish is a blow-off or drying of the forms.

Typical process flow

- 1 clean with ultrasonic 25 kHz, heated

- 2 - rinsing without ultrasound, cold

- 3 - preserve without ultrasound, unheated

- 4 - drain or blow off with compressed air

may be dry with circulating air up to 110 ° C

any special equipment

- Downdraft in the upper area

- Thermal insulation of the single Chambers

- Oil separator for external installation

- Fresh water inlet valve or solenoid valve for filling the basin

- Lifting system with oscillation

Advantages at a glance

- Avoiding time consuming and kostenintesiver hand cleaning

- Improvement of cleaning results

- Cleaning in complex geometries

- Improving the quality

- Boost productivity