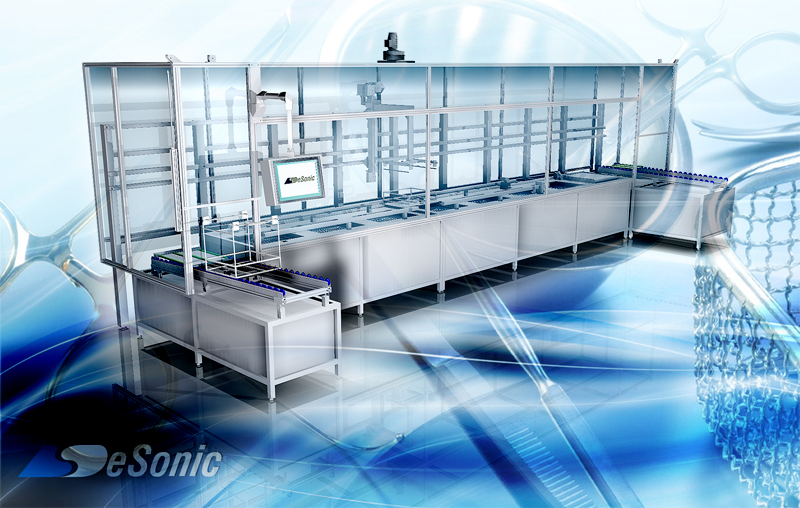

for cleaning and passivation of surgical instruments

(according to ASTM A967-05)

Cleaning and passivation with ultrasound

In the processing of workpieces / products with complex geometries, E.g. surgical instruments or products of for medical technology, stainless steel will damage the surface"" so that oxygen entry is eingschränkt to the natural passivation freely accessible surfaces.The steel surface is not completely passive corrosion can occur, even if the grade under the given conditions usually considered resistant. To avoid this, a passivating of workpieces should necessarily take place.

The prevention of intensive, time consuming hand cleaning and to improve the cleaning performance is the advantages of ultrasonic cleaning and passivation in a plant. The failure rate or review due to corrosion are reduced or lifted.

Surfaces must be clean, i.e. free from:

- organic dirt, lubricants, oils and fats

- Scale, scales

- Surface layers that are impoverished due to the formation of tarnish or oxides chromium

Pickling and passivating stainless steel

Publication of Euro Inox

Typical process flow

- 1 clean with ultrasonic 40 kHz

- 2 - wash with city or Demineralised water

- 3 passivation with ultrasonic 40 kHz

- 4 - rinse with city or Demineralised water

- 5 - rinse with Deionised water

- * - Dry with circulating air or process air-abrade

any special equipment

- Downdraft in the upper area

- Thermal insulation of the single Chambers

- Oil separator for external installation

- Fresh water inlet valve or solenoid valve for filling the basin

- Lifting system with oscillation

Advantages at a glance

- Avoiding time consuming and kostenintesiver hand cleaning

- Improvement of cleaning results

- Cleaning in complex geometries

- Improving the quality

- Boost productivity

- Passivate to ASTM A967-05