for optics, vacuum technology and Feinstmechanik

Fine str agreement systems

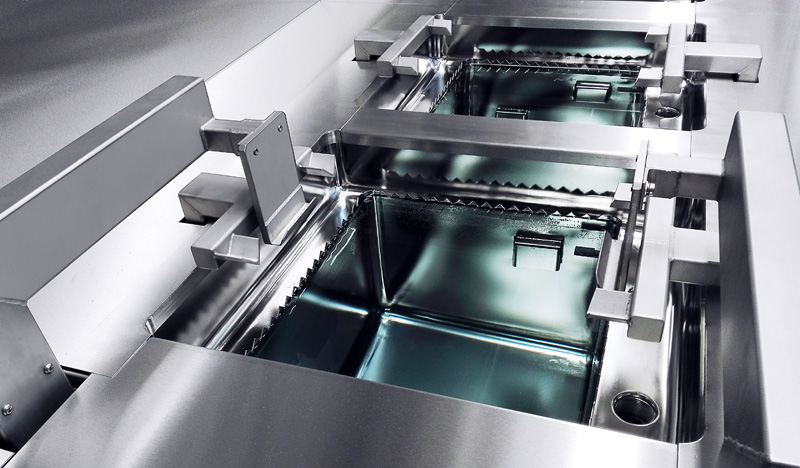

Fine cleaning also check maturity or is coating maturity cleaning the cleaning of mostly round or rectangular lenses or products with highest cleaning requirements, E.g. for high vacuum applications. This type of cleaning is composed of different single processes such as cleaning, cleaning, neutralizing, flushing, fine - Feinstspülen and drying.

The fully automatic systems will equip this with the carrier loaded on a conveyor belt or directly from the originating station. The stored in the program process and parameter settings for each process to be performed fully automatically by choosing a program and it starts. This process can be saved for documentation or reproducibility in turn with specified sizes as a platform-independent file optional.

Because mostly in clean rooms of different classes are set up these systems the technical design of the plant is also the installation site according to. So, cracks and joints where can dust off or moving parts such as motors and engines due to the dust be avoided or reduced to a minimum.

A possible conclusion of the critical cleaning in the optical industry represents the drying to disinfect. This type of drying allows a completely water-free and particle-free surface of the products.

Typical process flow optics

- Before cleaning

Ultrasonic 25 kHz, heated - solvent A3 - Cleaning

40 kHz ultrasonic, heated - alkaline - Flushing

with city water, heated - Cleaning

40 kHz ultrasonic, heated - neutral - Flushing

with city water, heated with cascade 3 - Flushing

with Deionized water, heated - Flushing

with Deionized water, heated with cascade after 6 and a conductivity < 0.2 µS, lift - Drying

with warm air, infrared, vacuum, or isopropyl alcohol (IPA) attention: ATEX

Fields of application of fine / critical cleaning

- Optics in various types and form

- High vacuum parts

- Precision parts with any residual dirt

- ...

any special equipment

- Downdraft in the upper area

- Thermal insulation of the single Chambers

- Oil separator for external installation

- Fresh / VE water inlet solenoid valve to fill the basin and control the Cascades

- Oscillation in all basins

- Containment of the system in the upper area with acrylic glass and if necessary a steam suction

- Storage / print process data as a file to reproduce / QMS